The production process, carried out completely within our facilities, has made us become a single point of reference for our customers, who can thus rely on only one partner for the realization of their projects.

This strength allows constant control over the quality of the products and theefficiency of the production cycle itself.

We work side by side with our customers, right from the early design stages, to suggest the best solutions in terms of materials, types of processing and quality of results.

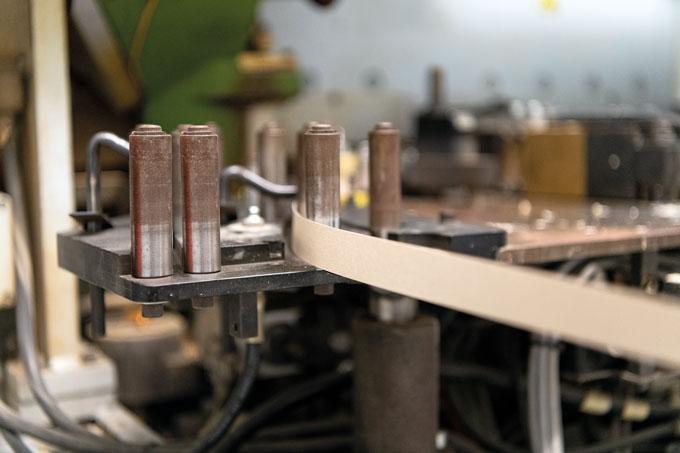

Our constant commitment to investing in technologies and machinery allows us to respond quickly to the demand for flexibility in our sector and allows our work team to enrich their skills and know-how.